Translated from German to English using Google Translate

Testing Pro-Line PRO-2 2WD Short Course-Truck

Traxxas kicked off an avalanche with the release of the Slash in 2009, would have held at that time hardly anyone possible. What was intended as a pure fun car and robust alternative to known RC vehicle shapes such as monster trucks and buggies, also conquered the hearts of diehard off-road racers in the storm. Short Course racing classes sprouted in the following years like mushrooms out of the ground and made off-road events thanks to a manageable cost again for a wider field of participants interesting.

Today, about half a decade later, Short Course Trucks are from virtually all major manufacturers to have in a variety of styles and price ranges that vie for the attention of buyers. The most popular truck of all is and remains still the good old Slash, which shines with an indestructible body and a range of applications, which is as wide as in almost any other RC car off-road area. Not quite innocent of the long-term success are the many tuning parts with which you can transform the slash at will in a scale-Truck or from a true racer. One of the most ambitious tuning parts manufacturer is Pro-Line from the USA, who have recognized the potential of the Slash very early. From the large range of different “Performance Parts” for the Traxxas truck Pro-Line has with the PRO-2 put together a complete package that combines all parts in one kit.

To be precise, the term “kit” is not entirely correct, since a part of the PRO-2 is delivered pre-assembled. The gearbox, the chassis plate in the damper, steering unit and the wheels are assembled at the factory, which shortens the construction period. The kit – which actually no one is as I said ![]() – also are an unpainted Flo-Tek body with two large decal sheets, a Pro-Trac Suspension kit, an Adjusting tool for threaded rods, 5000 Difföl, a large bottle of 30s shock oil as well as illustrated instructions for.

– also are an unpainted Flo-Tek body with two large decal sheets, a Pro-Trac Suspension kit, an Adjusting tool for threaded rods, 5000 Difföl, a large bottle of 30s shock oil as well as illustrated instructions for.

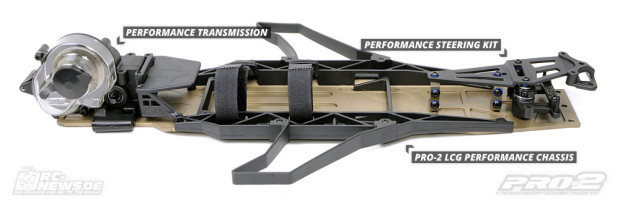

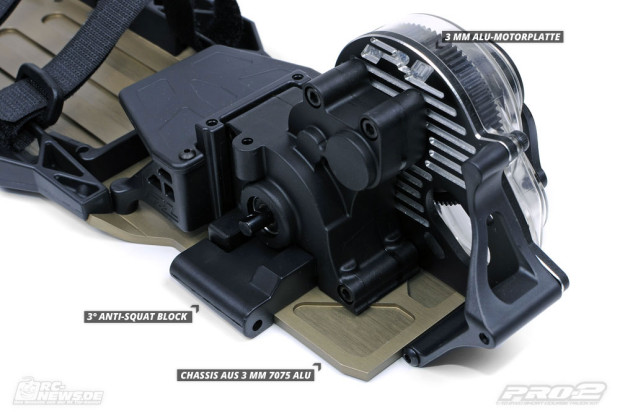

Basis for the PRO-2 forms a narrow chassis made from 3mm 7075 aluminum with side reinforcements made of plastic. In the Page Elements three tabs for battery Velcro straps and flexible mounts for Nerf Bars (Seitenrammer) are integrated. Towards the two chassis ends go to the page elements into reinforcing elements. Thus, the rear bulkhead is based far from the front, the front you will find a short Topdeck made of plastic, which also serves as a holder for the transversely installed steering servo and the steering.

Pro-Line has the PRO-2 is a four-fold ball bearing steering unit made of plastic with an adjustable servo saver donated, which should still provide a few headaches. More on this later. Through the ball bearing, the steering is extremely smoothly and virtually no play. Due to the compatible with the Slash design of the steering, the steering servo must be mounted transversely. Thus this is particularly easy to get to and changed in case of damage within minutes.

Precious seems to the CNC-machined, 3mm thick aluminum motor plate at the other end of the chassis. By additional millings on the back of the surface, which can be used to derive the heat from the engine increases. The small plastic support at the rear end of the motor plate is a remnant from Slash times and is no longer used in the PRO-2. At this point, is screwed at a later stage of the Heckrammer. Under the transmission is the one-piece bracket for the rear suspension arm. By default, a holder with 3 ° Kickup is included, further anti-squat blocks with 2 °, 4 ° and 5 ° are also available.

In the closed and well-greased gearbox you find a top and idler gear made of steel and a Kegeldiff made of durable and lightweight plastic and metal. The oil-filled 4-spider diff is sealed twice on the outputs and provided with metal plate wheels which run on thin shims. Double Sided provided with rubber gaskets ball bearings ensure a smooth running of the entire transmission unit.

Our differential was filled not completely clean from the factory and had lost on the delivery route something Difföl, which was located partially within the transmission housing. Because Pro-Line a small bottle 5000 Difföl (probably knowingly?) Has settled, the problem is quickly out of the way. By the way, you can see the seals on the lid and the two outputs of equal treat with a thin layer of “Green Slime”, so that the oil stays where it should.

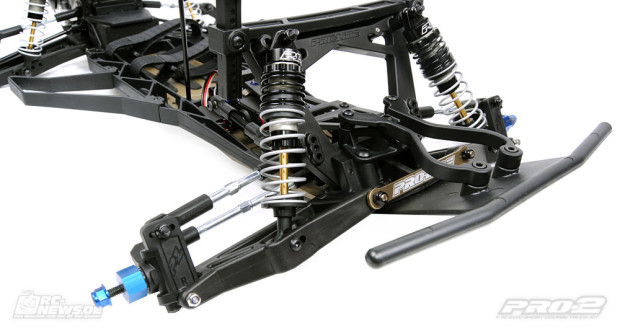

Built completely finished, but not yet filled with oil, the supplied Power Stroke dampers are. The aluminum dampers is Small Bore Big Bore shocks with springs and coated 3.5mm piston rods. Pro-Line combines the advantages of Small Bore shocks like a lightweight with the better performance of big bore springs with the Power Stroke dampers. As a special treat, the dampers are equipped with two-stage springs. The short black feathers are very soft and take on all the little bumps, while the lower, gray feathers are responsible for Grobe’s. Conventional Big Bore springs can also be used with the Power Stroke dampers.

Pro-Line could not resist from giving the PRO-2 is a set of complete wheels clean bonded “Made In USA” for the equivalent of about 80 euros. These consist of the black F-11 spoke wheels, blue “Closed Cell” tires inserts and Blockade SC tires in the rubber compound M3 (Soft). The grippy tires are recommended for slightly dusty to dry hard packed surfaces and are classified between the Holeshot and Caliber.

Matt Wallace of Pro-Line Interview

For the history of trucks we have Matt Wallace from the R & D team of Pro-Line under a short e-mail interview. Matt is responsible for a large part of the PRO-2 SC development and is part of the PL-racing team.

RC News.de: Hi Matt, when did you come up with the idea of releasing a full kit? Already at the release of your first Performance Parts for the Slash or later?

Matt Wallace: Once we had the ProTrac kit, Transmission and Chassis completed and after running the parts together at our local tracks and really enjoying the performance and durability, we made the decision to complete the rest of the parts required to finish the PRO-2 kit.

RC News.de: Would you recommend the PRO-2 SC only to hardcore racers or Bashers as well?

Matt Wallace: The PRO-2 SC is unique in this respect because it definetly has the speed to be raced, but also has the durability to be bashed. So to speak, the best of both worlds!

RC News.de: Will there be optional Pro-Line parts for the PRO-2 SC like a BallDiff, a Sway Bar Kit or Carbon Fiber Parts in the future?

Matt Wallace: You can be sure that we will continue to develop the PRO-2 and the racers will deliver more cool upgrades in the future!

RC News.de: Is it possible to use your “old” Slash bodies on the PRO-2 SC, without drilling new body post holes?

Matt Wallace: Yes, definitely! Bodies that originate from Slash fit easily on the PRO-2 SC.

RC News.de: Will there be on your side in the future more setups of your team riders like Nick Blais or Ty Tessman to download?

Matt Wallace: We currently have three setup sheets available for the PRO-2 SC: stock, indoor and outdoor. As soon as we have more racing experience with the PRO-2 SC, we will add more setups. The setups can be found here:http://prolineracing.com/pro- 2/build .

RC News.de: Thanks for the interview Matt!

Assembly of the PRO-2

Due to the high degree of pre-fabrication one has to deal only with the body, the suspensions and the installation of the electronics. Even inexperienced wrench do not need more than one day of construction until the drivable Pro 2 is on the craft table. The instructions are settled exclusively in a an English version, the individual construction phases are characterized by a good imaging practically self-explanatory and also to create without knowledge of English.

One of the numerous features on the PRO-2 are the body mounts. Attached is the Flo Tek body not with spring clips but, similar to the Corally chassis, with Plastic knurled nuts that have M4 threaded inserts made of metal. Due to the small o-rings on the lower holders the body against any play and does not rattle even the roughest terrain use.

Extremely robust, the R / L-threaded rods and the ball joints are designed. Made of steel with M4 threads, they should not break or bend so fast. A small (very sharp-edged) Adjustment Tool for adjusting the track, and the camber is attached. Tip: The threaded rods can be assembled much lighter and adjust later if you greased the threads easily before.

Also a very robust making the drive shafts. Again, used Pro-Line 4mm round material which Diffseitig is slightly tapered to allow the Outdrives enough space during compression. The pin in the joint is held by a retaining ring made of metal and a grub screw in the center of the axis. Tip: Regularly a thin layer of dry lubricant (such as Finish Line Dry Lube, etc.) apply to the drive shafts, to increase the ease of movement.

Tuning Factory: Sitting on the wheel axles hex wheel hub from blue anodized aluminum with integrated locking screws. The lug nuts are also blue anodized made of lightweight aluminum and interlocked on the flange-back. As a little extra to sit in all ball heads made of aluminum-coated beads.

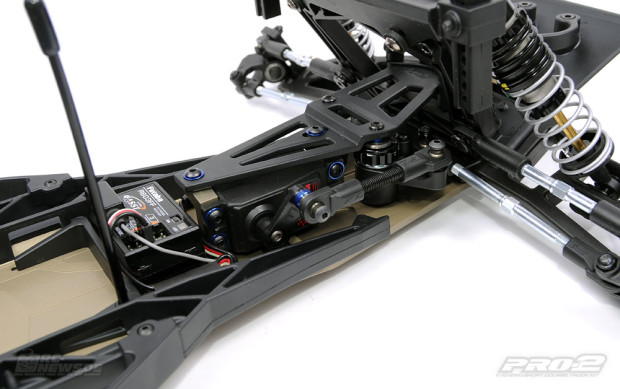

The steering servo sits under a short plastic top deck to supports made of aluminum. The front of the two brackets is only bolted to the upper deck in a slot and is only supported on the chassis plate below. If the battery is mounted at the front, leaving little space for the receiver behind the servo.Nevertheless is sufficient for a standard receiver eg Futaba or Sanwa space available.

At the front, there are several settings for the upper arm or the roll center, a total of three in height and three in length. For the damper can be found on the wishbones two mounting positions, as well as the top of the shock tower. Striking is the easy, maintenance-friendly and straightforward structure, the PRO-2 has inherited from Slash.

Back there at the wheel carriers six mounting positions for the upper arm, to the shock tower three.In addition, the wheel can be mounted in two heights on the lower wishbones. Pro-Line PRO-2 is on a no E-clips for mounting the wishbones are fitted bolts and lock nuts are used.

Without spacers in the shocks, the truck offers more than enough ground clearance, even for the heaviest terrain over 60 millimeters are in quite the rebound state feasible. This large suspension travel is possible by very long outdrives and drive shafts that are slightly tapered at the rear end.

Can be adjusted through a large opening in the transparent gear cover with a 7 mm socket wrench, remove the vented clutch Rusch. The cap rubber is connected to the cover by means of a flap and it can not be lost. Tip: Never ride with the gear cover or without cover screws. Both screws are an integral part of the gear unit!

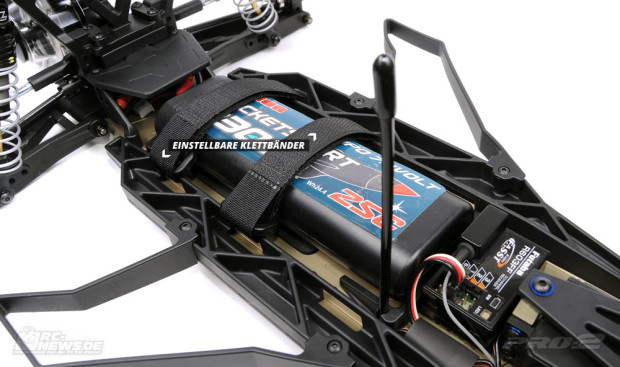

In the PRO-2, the battery pack is kept with black Velcro strips in the chassis. The freely adjustable straps wide variety of battery types can be used, even for a 3s LiPo is still sufficient room for improvement exists. The antenna mount is integrated into the small battery stopper. For the ESC, there is a mounting plate directly in front of the rear shock tower, which can be removed by loosening two screws.

The chassis is an unpainted Flo-Tek body. The peculiarity of the Flo-Tek are the many areas that can be cut without affecting greatly the stability and appearance of the body. Especially with jumps and strong winds improve these excerpts the drive or jump behavior significantly. But watch out: The holes must be cut in all race series. If in doubt, always check the regulations beforehand, before the body for racing “unusable” is.

In Heckbreich the body can be cut free at the sides, both in addition to the three large holes in the middle and at several points. Small winglets and number plates to stabilize the truck at high speeds.To fix the one-piece side panels are lightweight aluminum screws with plastic nuts at, by the way the single inch screws in the entire kit. The PRO-2 is otherwise fully equipped with metric screws and nuts. As the wheels and the suspension is also the body of “Made In USA“.

Was used for the “5-minute painting” one stored with silver (# 28205) Metallic Blue (# 28201) and black (# 28113) of LRP. The discs have been with Translucent Orange Tamiya darkened (# 300 086 043).

Practice Test: Pro-Line PRO-2 race

The first exit of the PRO-2 took place during the second run of the Five-Days, one of the most popular electric off-road events in the sport of west. The organizing club AMC Langenfeld conjured up for the two-day event in just a few hours a technically challenging, but still fun to be traveled indoor race track from carpet, wood, and miles of tape on the Long Fields floor. Changing Untergünde and many close 180 or 90 degree bends required a sensitive gas finger and lightning-fast reactions, they wanted to quickly get around the course.

Despite “carpet USEFULLY” tires with the stock setup was very soft (DBoots terabytes / Nanobyte) expected to win a flower pot. With a harder damper oil (VA: 60WT/HA: 40wt), spacers in the dampers and without the upper, soft feathers was the truck’s better to drive. However, it was missing, particularly in fast bends, from the steering wheel. Up to 80 grams of lead on the front axle and a more aggressive setup with more toe and a lower roll center brought only minimal improvement, the car was simply not around the corner. It was only the tip of an “old-Slasher” to fix the soft servo saver with super glue and remove the spring, brought the desired success. At this point, many thanks to Kevin Klump, from which came the decisive tip!

With the fixed servo saver the car was unrecognizable, from then it was precisely and accurately even to the tightest bends. Without further changes to the setup, reduced the lap times of around 21 seconds to 20 seconds. Partly Traction Rolls that occurred through the multiple the steering wheel, it was necessary to get a handle on the connection. With less weight (10 grams per C-hub) and toe (0 °) on the front axle, the truck was again much easier to blast around the tight course. In the end it was enough (17.5 T motor without power program) for placement in the midfield in the 2WD Short Course Stock class. For the first use of a good result, but certainly still be improved.

Conclusion

Pro-Line connects the PRO-2 sent the genes of Slash with those of a real racers. The result is a virtually indestructible truck that feels comfortable not only in racing conditions, but like his ancestor, also off-track. Points, the PRO-2 with its maintenance-friendly design, the many standard tuning parts, a very good set of wheels, a high-quality Flo-Tek body and a high manufacturing quality of all components.

In total, more week test period with multiple exits, both in-and outdoors, no damage occurred. Also in terms of wear resistance of the PRO-2 is to be settled in the top class, even seizing marks are the outdrives to recognize the drive shafts or the main gear. Only with the too soft spring in the servo saver to Pro-Line makes an avoidable gaffe.